These 7 elements are essential for creating and managing a productive LOTO program (lockout tagout).

Having an effective Lockout Tagout (LOTO) program can be the difference between saving a life and losing one. While this may sound dramatic, it is true. LOTO programs are essential for ensuring the safety of employees who work on or around hazardous energy sources. Without them, employees can be vulnerable to serious injuries and workplace accidents.

The value of lockout tagout was evidenced by an incident at a Thermoid rubber manufacturing plant in 2023. Everything changed for a young 25 yr. old worker in an Ohio facility when his company’s failure to properly implement lockout tagout procedures led to a series of severe injuries and immediate hospitalization. This case and so many others raise awareness as to why creating an effective LOTO program is so vital. After all, the worker’s injuries were entirely preventable.

This article looks at 7 program elements that companies and organizations can focus on to avoid tragedies like the one that struck in that rubber manufacturing facility. It will provide a framework for building a LOTO program that not only safeguards employee lives and machinery, but also the future of the company.

Why an Effective LOTO Program Matters

Building a vibrant and reliable loto program takes work. Therefore, it pays to understand the reasons behind your efforts.

First, let’s go over the purpose of lockout tagout and LOTO programs.

Lockout tagout is a process that is meant to control the release of hazardous energy—such as electrical, mechanical, hydraulic, and pneumatic—so that machines remain safely isolated and powered down while work is performed. A LOTO program works to support these energy control efforts. When a LOTO program is properly designed, implemented, and maintained, it provides critical safeguards that protect employees from serious, even fatal, injuries.

Second, what are the impacts that effective lockout tagout can have?

- Preventing Workplace Accidents and Injuries

- Compliance with Regulatory Standards

- Protecting Productivity and Reducing Downtime

- Building a Culture of Safety

- Supporting Employee Morale and Retention

- Minimizing Liability and Financial Risks

- And So Much More!

Though these impacts are all profound in their own right, let’s take a minute to focus on the two reasons companies and organizations REALLY care about lockout tagout.

- Employee Safety

- Cost Savings

Employee Safety:

Companies are charged with the responsibility to protect their workers. They are expected to make any necessary efforts to produce a safe work environment and reduce risks, and for good reason. Employees are like the lifeline of the company. It is vital that organizations do their part to ensure worker safety, as there are many repercussions that can result from negligence. Some of these potential consequences include loss of operational efficiency, distrust among workers, possible lawsuits or hospital bills, and more.

Cost Savings:

Finances are what make it possible for companies to grow, expand product offerings, and become more profitable. Companies don’t want to be dedicating their hard-earned profits towards managing disasters that could have easily been avoided with proper lockout tagout procedures. By not correctly and consistently performing LOTO, companies can leave themselves vulnerable to issues such as reputational damage, the need for more frequent hires, replacements of expensive equipment, and loss of manpower for worker’s comp. Not to mention, there can be large OSHA fines given to companies who are found violating the established safety requirements.

This section highlights that there are more than just a couple reasons for companies to be concerned about creating an effective LOTO program. Companies who are anxiously engaged in trying to prevent accidents will reap the benefits and companies who take a lackadaisical approach may find themselves wishing they’d been more attentive.

7 LOTO Program Aspects To Focus On

There are a lot of elements that go into building a functional and efficient LOTO program. However, these various elements can be distilled into 7 main categories, listed below.

- Comprehensive Written Procedures

- Proper Training and Education

- Periodic Inspections and Audits

- Documentation and Reporting (with software!)

- A Culture of Safety

- Management and Worker Participation

- Continuous Improvement

In the following sections, we will do a deep dive into each one of these program elements, talking about key elements, importance, and more.

1. Comprehensive Written Procedures

What It Involves: One of the fundamental components needed for a LOTO program is a set of detailed, written procedures for controlling hazardous energy. These procedures serve as a set of instructions for workers to follow in order to properly perform lockout tagout on machinery. As such, procedures must be specific with step-by-step directions for safely isolating and locking out energy sources. These procedures need to be regularly utilized and fully completed.

Key Elements:

- Equipment-specific procedures: Each procedure should identify the specific equipment it is meant for and have specialized instructions for it. Procedures for different kinds of equipment will often be similar, but not identical.

- Step-by-step instructions: The procedure should clearly outline the sequence for isolating and locking out the equipment, from shutting down to verifying isolation.

- Energy source identification: Clearly identify all energy sources, including electrical, mechanical, hydraulic, and pneumatic, that need to be isolated.

Why It’s Important: Providing clear, easy-to-understand instructions minimizes the risk of human error. Workers need to know exactly what steps to take and how to execute them safely, ensuring no energy is accidentally released during maintenance or repair. If you’re unsure how to get started writing lockout tagout procedures, don’t worry. We have an article with tips to help!

2. Proper Training and Education

What It Involves: In order for employees to effectively participate in and help run a LOTO program, they need to be well educated. This means that it is essential for programs to provide thorough and ongoing training for all employees involved in the lockout process. So, who all needs training? Training should be given to authorized employees (those performing the lockout), affected employees (those working nearby), and all other employees who may be impacted by the lockout.

Key Elements:

- Initial and refresher training: Employees must receive comprehensive training on lockout tagout procedures when they are first hired, along with an annual refresher course to reinforce knowledge.

- Role-specific training: Authorized employees should be trained in the technical aspects of isolating energy, while affected employees should be made aware of the procedures to avoid inadvertently tampering with locked-out equipment.

- Documentation of training: Records of training sessions should be maintained, ensuring compliance and tracking the effectiveness of the program.

Why It’s Important: Proper training ensures that employees are fully aware of the hazards involved and understand their role in ensuring a safe work environment. This reduces the likelihood of accidents due to unfamiliarity with the procedures or miscommunication. Not sure what proper lockout tagout training should include? See our pointers!

3. Periodic Inspections and Audits

What It Involves: To ensure that your program remains effective over time, there need to be periodic inspections. Along with that, yearly audits of the program need to be conducted to prove compliance, identify gaps in the process, and verify that employees are following procedures correctly.

Key Elements:

- Periodic inspections/audits: A formal audit of the LOTO program must be conducted at least annually, as required by OSHA, to evaluate the effectiveness of procedures.

- Regular check-ins: Every once in a while, managers should do a surprise check-in to verify that procedures are being performed, employees understand their roles, and that there aren’t any major issues needing to be addressed. These are less formal than audits.

- Corrective actions: Any deficiencies found during inspections must be addressed immediately through retraining, procedure updates, or other corrective measures.

Why It’s Important: Periodic inspections help ensure that the LOTO program is being consistently followed and that it evolves to address any emerging risks or procedural inefficiencies. Additionally, smaller audits can provide a healthy check-up on the program. This proactive approach helps to prevent accidents and maintain compliance with regulatory standards. Want to learn more about how our software can be used to conduct periodic inspections? Click to learn more.

4. Documentation and Reporting

What It Involves: Accurate documentation and reporting are essential for tracking compliance, identifying areas for improvement, and maintaining transparency in your LOTO program. While it isn’t necessary, much of the industry is shifting towards digital reporting and documentation. After all, software can significantly streamline this process, ensuring that all lockout activities are recorded, accessible, and easy to manage. Regardless, companies need a reliable system for recording LOTO program data, storing it, and being able to retrieve it in the future.

Key Elements:

- Incident tracking: Any incidents, near misses, faulty equipment, etc. need to be recorded so that management can use it to analyze trends and identify risks. Software can aid with this by providing reminders when actions need to be taken to fix issues.

- Complete, accurate reporting: Any lockout tagout procedures that are performed should be recorded with details such as which machinery and set of procedures were followed, by whom, and when. Software allows you to input these details while performing the procedure.

- Audit trails: Programs need to have a system for storing the data and history of each lockout tagout event, including inspections, lock applications, and removals.These records are needed for showing compliance during audits. With software, it’s easy to group all of this data together.

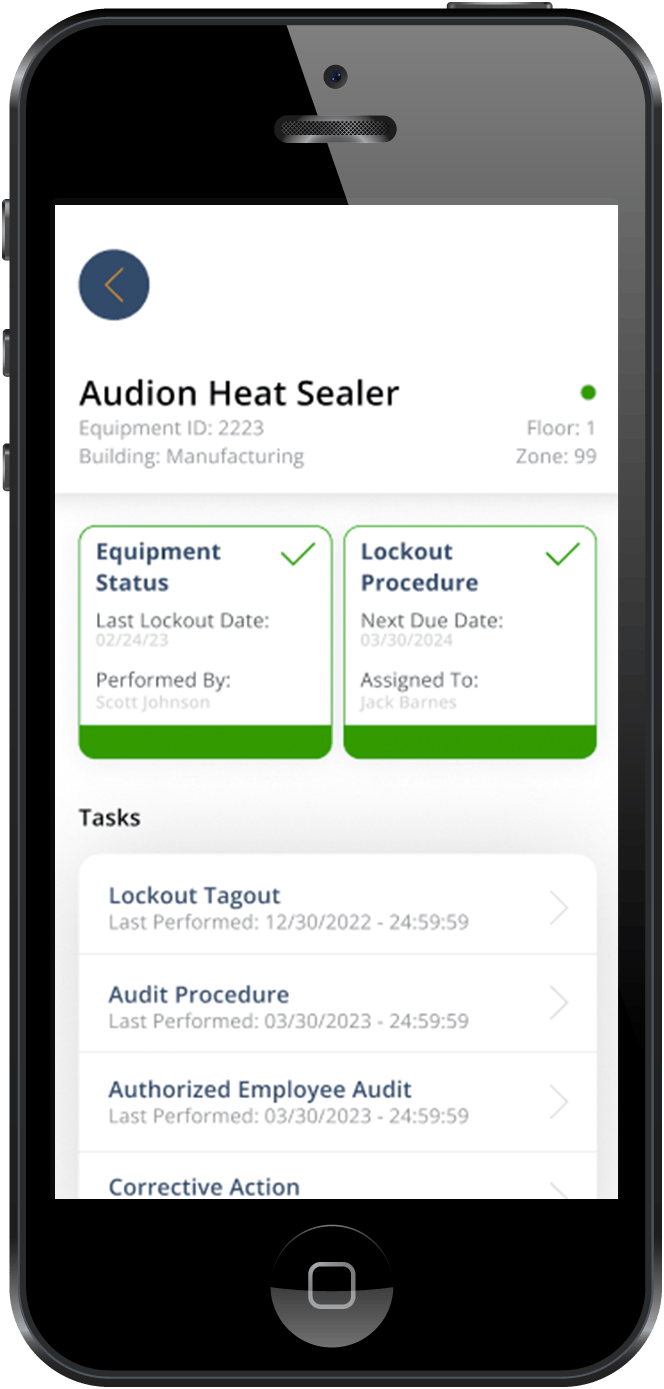

- QR code integration: With QR code technology, employees can easily scan equipment to bring up the relevant lockout procedures, track lockout status, and ensure that proper steps are followed.

Why It’s Important: Effective documentation helps maintain compliance with OSHA regulations, but it also provides a detailed view of how procedures are being implemented. Documentation helps keep employees accountable for their efforts. By leveraging software, organizations can ensure that records are accurate, up-to-date, and readily available for audits or inspections. Automated reporting also reduces administrative burdens, freeing up more time for proactive safety measures.

5. A Culture of Safety

What It Involves: For a LOTO program to thrive, it must be part of a larger culture of safety within the organization. A culture of safety prioritizes employee well-being, encourages proactive safety practices, and ensures that safety is seen as a shared responsibility.

Key Elements:

- Visible commitment: Management should consistently demonstrate their commitment to safety by ensuring that LOTO procedures are followed at all times and providing the necessary resources for training and equipment.

- Open communication: A strong safety culture allows for open communication about potential risks, where employees feel comfortable reporting hazards or suggesting improvements to LOTO procedures without fear of retaliation.

- Safety recognition: Rewarding employees who consistently follow safety protocols and participate in safety initiatives reinforces positive behavior and contributes to a safety-first mindset.

Why It’s Important: A strong culture of safety goes beyond compliance and instills safety as a core organizational value. When employees see that safety is prioritized at all levels, they are more likely to adhere to LOTO procedures and other safety protocols. This cultural shift helps prevent accidents and fosters a more engaged, safety-conscious workforce. Want tips for building a culture of safety? Read our article!

6. Management and Worker Participation

What It Involves: Both management and workers must be actively involved in the LOTO program for it to be successful. A top-down approach from management combined with grassroots engagement from workers ensures that the program is practical, comprehensive, and adhered to by everyone involved.

Key Elements:

- Management’s role: Leadership should set the tone by investing in safety training, regularly reviewing the effectiveness of LOTO procedures, and ensuring resources are available to maintain compliance.

- Worker involvement: Employees should have a voice in the development and continuous improvement of LOTO procedures. Involving them in risk assessments, procedure development, and safety audits increases buy-in and ensures that procedures are realistic and effective.

- Joint safety committees: Establishing committees that include representatives from management and the workforce can help facilitate communication, resolve safety concerns, and ensure LOTO procedures are applied consistently.

Why It’s Important: Collaboration between management and employees helps ensure that safety initiatives, including LOTO, are well-informed, effective, and sustainable. Workers who feel involved in the development of safety procedures are more likely to follow them, and management’s visible commitment reinforces the importance of those efforts.

7. Continuous Improvement

What It Involves: A successful LOTO program isn’t static. It requires ongoing evaluation, adjustment, and improvement to remain effective in the face of new equipment, changing regulations, or lessons learned from incidents. Continuous improvement is a proactive approach to safety, focusing on evolving and optimizing LOTO processes over time.

Key Elements:

- Regular reviews and audits: Routine assessments of the LOTO program, including periodic audits, should be conducted to identify any gaps in procedures, documentation, or compliance.

- Feedback loops: Encourage feedback from employees on the ground, who are in the best position to identify issues or inefficiencies with current procedures. Management should use this input to refine and improve LOTO practices.

- Incident analysis: If a lockout-related incident or near miss occurs, it’s critical to analyze what went wrong, adjust the relevant procedures, and retrain employees as needed to prevent future occurrences.

- Technology updates: Staying informed about new technologies, such as updated LOTO software or equipment, can enhance your program’s efficiency and effectiveness.

Why It’s Important: Safety is an ongoing process, and no program is ever perfect. Continuous improvement ensures that your LOTO program evolves to meet new challenges and better protects workers over time. By regularly reviewing, updating, and enhancing your procedures, you minimize the risk of accidents and maintain a high standard of safety.

Key Concepts to Understand

Reading over these 7 elements of an effective LOTO program may feel overwhelming. You may think of your current program (or lack thereof) and feel unsure where to start. Here are 3 key lessons to remember when trying to build or improve a LOTO program.

- Lesson #1: Change Takes Time

- Each of the 7 aspects of a LOTO program can take a significant amount of time and energy to cultivate. It’s important to understand that progress is a journey and that developing a safety program is going to be ongoing. This is not a linear process. There will likely be setbacks. However, even seemingly small changes can have a lasting impact.

- Lesson #2: Feedback is Key

- While there are certain established restrictions that need to be followed for lockout tagout, there is also a lot of room to customize your LOTO program. Spend time talking with your team to figure out what ways of scheduling, performing procedures, and documenting information work best. The more feedback you get, the better you can mold the program to fit company needs and gain buy-in from employees.

- Lesson #3: Get Help From Others

- Whether it be support from the company owner or a team you work on, don’t try to tackle the LOTO program alone. Collaboration with others will improve ideation, operational flows, and outcomes. Having help from others can support efforts to develop the program.

Using Software to Create an Effective Program

There are many reasons that organizations choose to incorporate inspection software into their lockout tagout programs. Some of the advantages to using Smart Safety Pro software, include:

- Customizable procedure building

- Paper-free documentation

- Detailed audit history

- Wifi is not required for use

- Organized information stats

- On-the-go reporting

These features help with simplifying transparency, increasing efficiency, improving transparency, and so much more!

To learn more about how Smart Safety Pro software could aid you in performing lockout tagout, request a demo!

Conclusion

Building an effective LOTO program requires a comprehensive approach that includes clear procedures, employee training, and periodic inspections and a system for documentation and reporting. In addition, fostering a culture of safety, ensuring management and worker participation, and embracing continuous improvement are all critical to maintaining a robust, sustainable safety program. These elements work together to protect workers, reduce risk, and ensure compliance with safety regulations, ultimately contributing to a safer and more productive workplace.