A beginner’s guide to performing lockout tagout procedures with QR codes and LOTO software.

In the workplace, ensuring worker safety during maintenance and servicing of machinery is a primary concern. Traditional lockout tagout (LOTO) procedures have long been the standard for controlling hazardous energy, but advancements in technology are offering new ways to enhance these safety measures.

The integration of QR codes and software solutions into LOTO procedures can significantly improve efficiency, accuracy, and compliance. This article explores the benefits of using QR codes and software to perform LOTO procedures and how these technologies can revolutionize workplace safety.

Where to Access Lockout Tagout Procedures

For companies who implement lockout tagout software, LOTO procedures can be accessed in 2 main ways: with written procedures and in the mobile software.

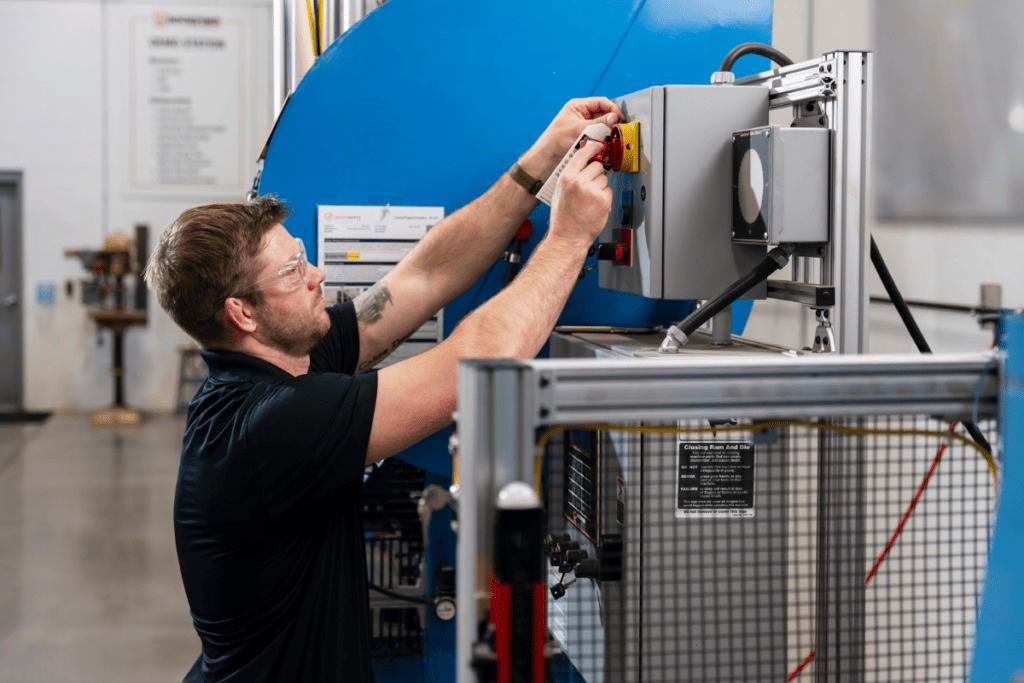

It is common practice for written lockout tagout procedures to be attached to/near machinery and equipment requiring lockout tagout. This way, workers who come to de-energize or shut down the machinery have easy access to their employer’s established LOTO procedures. These written procedures are often laminated to preserve their messaging and are secured to the machine using a cable tie or other form of reliable tether. These written procedures provide critical information such as the steps needed to safely de-energize hazardous energy sources, where the energy isolation points are, and how to return the equipment to service. (See more in-depth description in the next section).

Key Information Found on Written Lockout Tagout Procedures

Due to the unique circumstances and safety needs of individual companies, there currently is no formally established template that is required to be used in producing lockout tagout procedures. Because of this, most companies design their own template or modify one that they access online. That being said, many lockout tagout procedures have a similar look and contain similar, key information. This makes it so that procedures are easily identifiable by workers and readily understood, therefore promoting a safer workplace environment.

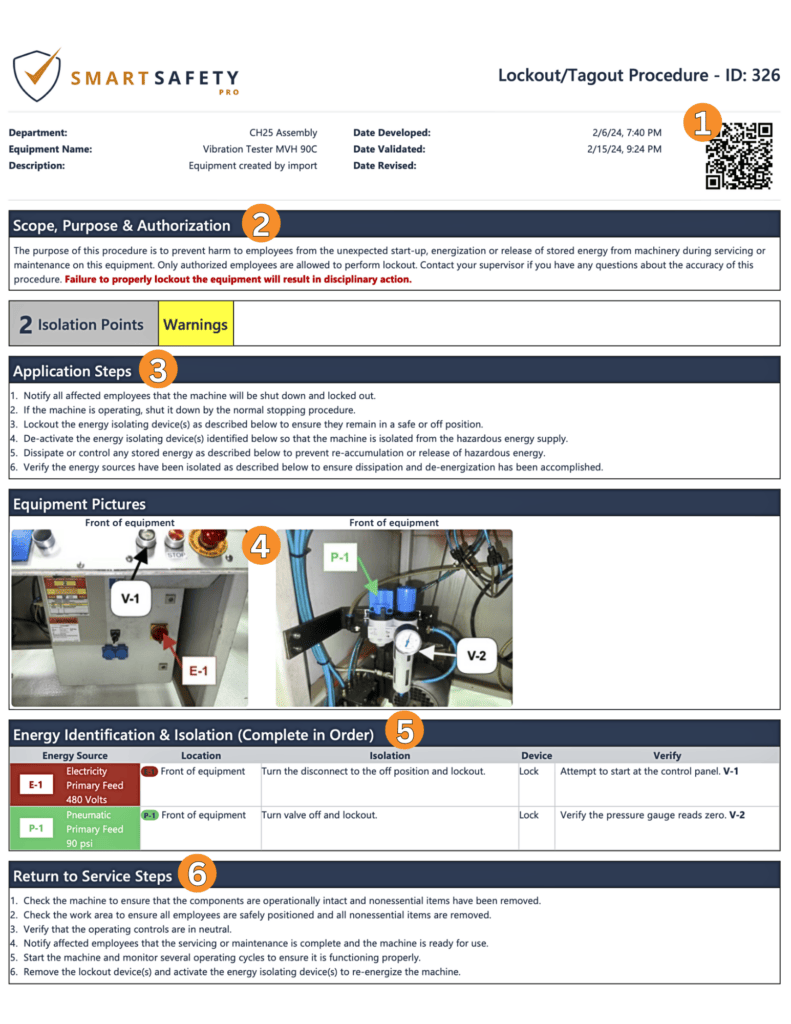

To give you an idea of what to look for on lockout tagout procedures and where to find it, here is an example template of written procedures.

1.QR Code

A QR code is a two-dimensional barcode that can be scanned using a smartphone or other mobile device to quickly access digital information. You can see an example in the upper right corner of the procedures.

A user who scans a QR code with Smart Safety Pro software can then immediately access an online database to fill out reports as they complete the lockout tagout procedures. This way, companies enjoy a paperless form of organized documentation. Additionally, scanning the QR code can log who accessed the procedure and when, providing an audit trail for accountability and compliance purposes.

2. Scope, Purpose, and Authorization

This section defines the range and objective of the LOTO procedure and specifies who is authorized to perform and oversee the lockout process. Specifying authorization and the type of lockout ensures that only trained and competent individuals perform and oversee LOTO procedures. This reduces the risk of errors and enhances accountability.

3. Lockout Application Process/Steps

The lockout application process/steps portion of procedures provides a detailed, step-by-step guide on how to safely apply lockout devices to isolate hazardous energy sources. Clear instructions minimize the risk of errors, ensuring that all necessary steps are completed in the correct order, thus preventing accidental energization.

Detailed steps ensure that every worker follows the same procedure, maintaining consistency and compliance with safety regulations. Each step included in this section is designed to systematically eliminate potential hazards, ensuring that all energy sources are properly isolated before maintenance begins.

4. Equipment Pictures

Visual aids, such as pictures of the equipment and energy isolation points, are included in the procedure. These can help the authorized worker(s) quickly identify the correct equipment and isolation points, reducing the chance of mistakes.

The purpose of visual aids is to complement written instructions, making it easier for workers to understand and follow the procedure. They can also be valuable for training new employees by helping them become familiar with the machinery and its components.

5. Energy Identification and Isolation

As you can see on the diagram, this section identifies the energy source type, details where it is found, and gives direction for isolating the energy source and verifying it has been correctly shut off.

This section provides crucial information to the worker by identifying all necessary hazardous energy sources and how to safely prevent accidental release of energy. This way, workers can create a safe environment to work in, protecting themselves and others from unexpected energization.

6. Return to Service Steps/Lockout Removal Process

This section outlines the steps for 2 key processes: safely removing lockout tagout devices and returning the equipment to normal operation.

The instructions outlined in this section should clearly indicate important steps such as verification that maintenance is complete, notifying affected employees before removing LOTO devices, and how to correctly re-energize the machinery. By providing simple guidance for removing lockout devices and returning equipment to service, companies help ensure that the machinery is safely transitioned back to operational status without risking worker safety.

We can see from this breakdown and the diagram above that each element of written lockout tagout procedures plays a crucial role in ensuring the safety and effectiveness of the LOTO process.

How to Use a QR Code in Lockout Tagout Procedures

While the exact steps for lockout tagout procedures vary, they typically look a little something like this:

- Prep for Shutdown

- Notify Affected Employees

- Equipment Shutdown

- Isolation of Energy Sources

- Lockout Tagout Device Application

- Dissipation of Residual or Stored Energy

- Verification of Isolation

- Performing maintenance or Servicing

- Release from Lockout Tagout

- Equipment Restart

- Documentation and Recordkeeping

So where does a QR code fit into all of that?

QR codes are attached to their coordinating equipment and can be scanned in a matter of seconds to pull up lockout tagout procedures and fill out reports during the LOTO process.

Companies can choose how to display their QR codes. Some opt to add them onto physical procedures that are printed and attached to the machine (as shown above). Others choose to simply attach the QR code to the machine. Either way, the QR code can be displayed with its associated piece of equipment.

To start a lockout tagout procedure, software users simply scan the QR code. This action pulls up the lockout tagout procedures for that asset and walks the user through each step of completing the procedure. From there, the user performs the usual steps, recording each one in the software as they go.

Ultimately, the purpose of QR codes in LOTO procedures is to initiate and simplify the process.

Not sure if it’s for you just yet? Read about the benefits below!

Benefits of Using Software and QR Codes in LOTO Procedures

There are a multitude of reasons why more and more companies are making the switch to use lockout tagout software and QR codes in their LOTO programs. Here we will highlight many of those reasons.

Streamlined Processes: QR codes streamline the process by enabling quick access to detailed LOTO procedures for specific equipment. By scanning a QR code, workers can instantly retrieve step-by-step instructions, eliminating the need to search through manuals or databases. Additionally, software solutions can automate various aspects of the LOTO process, such as tracking the status of lockouts and notifying relevant personnel of updates or changes. Through these software features, lockout tagout is organized and simplified.

Improved Efficiency & Time Savings: Faster access to information and automated workflows help reduce the time required to implement and release lockouts, minimizing equipment downtime and increasing productivity.

Elimination of Human Error: QR codes and software systems can ensure that the correct procedures are followed by linking the correct lockout tagout steps to their associated equipment. This reduces the risk of human error, which is a common cause of accidents in LOTO processes. Not only this, but the step-by-step verification helps with maintaining compliance by requiring specific actions to be completed before moving on to the next step, ensuring that no critical steps are overlooked.

Automated Documentation: Software solutions automatically log all LOTO activities, creating a comprehensive digital record. This documentation includes details such as who performed the lockout, when it was done, and any issues encountered. These digital records are easily accessible for audits and inspections, helping organizations demonstrate compliance with safety regulations and standards.

Real-Time Updates: QR codes and software systems can provide real-time updates on the status of lockout procedures. Workers and supervisors can instantly see which equipment is locked out, who is responsible, and when it is expected to be released. This results in readily available data and improved communication among team members.

Enhanced Collaboration: Digital platforms facilitate better communication and coordination among team members, especially during complex or group lockout situations. Multiple users can access and update information simultaneously, ensuring everyone is on the same page.

Detailed Audit Trails: Every action taken during the LOTO process is recorded in the software system, creating a detailed audit trail. This traceability helps in investigating incidents, identifying areas for improvement, and ensuring accountability. Since QR codes link directly to specific equipment and procedures, there is clear documentation of who performed the lockout and when, enhancing individual accountability.

Scalable Solutions: QR codes and software systems can be easily scaled to accommodate growing operations. Adding new equipment or updating procedures can be done quickly and efficiently within the digital platform. This scalability makes these solutions suitable for organizations of all sizes, from small businesses to large enterprises.

Try It For Yourself

As time goes on, more and more companies are making the switch and integrating software capabilities into their lockout tagout programs. With benefits such as paperless documentation and real-time updates, integrating software is a no-brainer for a lot of organizations. However, it makes sense to be hesitant or want to learn what you can before diving in.

At Smart Safety Pro, we don’t want you to just choose our software, but we want you to love your choice. To help you decide whether or not our program works for your situation, we offer free demos.

With a free demo, you can set up a time to meet with one of our professionals and talk about your organizational needs. This way, you can gather information and make an informed decision about what’s right for your company’s future.

Conclusion

Integrating QR codes and software solutions into lockout tagout procedures offers numerous benefits, including improved efficiency, enhanced accuracy, better communication, increased accountability, and scalability. By leveraging these technologies, organizations can not only streamline their LOTO processes but also significantly enhance workplace safety. As the industrial landscape continues to evolve, adopting digital solutions for LOTO procedures will be crucial in maintaining compliance, protecting workers, and optimizing operations.