This article details the top 10 most frequently cited lockout tagout violations and outlines what is necessary for compliance.

Lockout tagout (LOTO) procedures are critical for protecting workers from hazardous energy sources during maintenance, repair, and servicing activities. However, failure to comply with lockout tagout regulations can result in serious workplace injuries, fatalities, and regulatory violations. In this article, we’ll explore the top 10 most frequently cited lockout tagout violations and discuss strategies for addressing these workplace safety risks.

When it comes to workplace safety, the Occupational Safety and Health Administration (OSHA) is the governing body in the United States. In 2023 OSHA released a listing of their top 10 cited safety standards, of which 29 CFR 1910.147 The Control of Hazardous Energy (Lockout/Tagout) came in at number 6. In fact, this standard had over 2500 violations cited in the fiscal 2023 year alone. This high volume of lockout tagout violations along with the report are evidence that proper inspections and control of hazardous energy are priorities for OSHA.

In order to reduce the number of lockout tagout violations, this article dives into the most prevalent issues regarding compliance with standard 1910.147 and offers actionable solutions. After all, each of these violations could be avoided through effective preparation and preventative measures. By recognizing and addressing these issues early on, companies can build a strategy to avoid the hefty fines and other negative consequences of noncompliance.

Failing to have equipment-specific lockout/tagout procedures

This lockout tagout requirement, found in the OSHA standard 29 CFR 1910.147(c)(4), was the #1 most commonly cited section of the lockout/tagout standard in 2023.

Compliance Requirement: The lockout tagout standard (1910.147) requires that all forms of machinery, processes, or equipment that could create a hazard if they were unexpectedly started up during servicing, maintenance, or inspections (release of stored energy, injury to employees, etc) have their own written set of lockout tagout procedures. These written procedures should detail the steps for isolating energy sources, applying locks and tags, and verifying de-energization to ensure worker safety.

Common Employer Mistake: Most often, organizations receive a lockout tagout violation for this issue as a result of using generic procedures or failing to update procedures for new equipment. Generic or out-of-date procedures can lead to skipped steps, improper care, workplace fatalities, and large fines.

Strategy for Compliance: In order to avoid this lockout tagout violation, develop detailed lockout tagout procedures for each piece of equipment, outlining the steps for isolating energy sources, applying locks and tags, and verifying de-energization. Additionally, ensure that these procedures are specific to the equipment’s unique energy sources, configuration, and maintenance requirements.

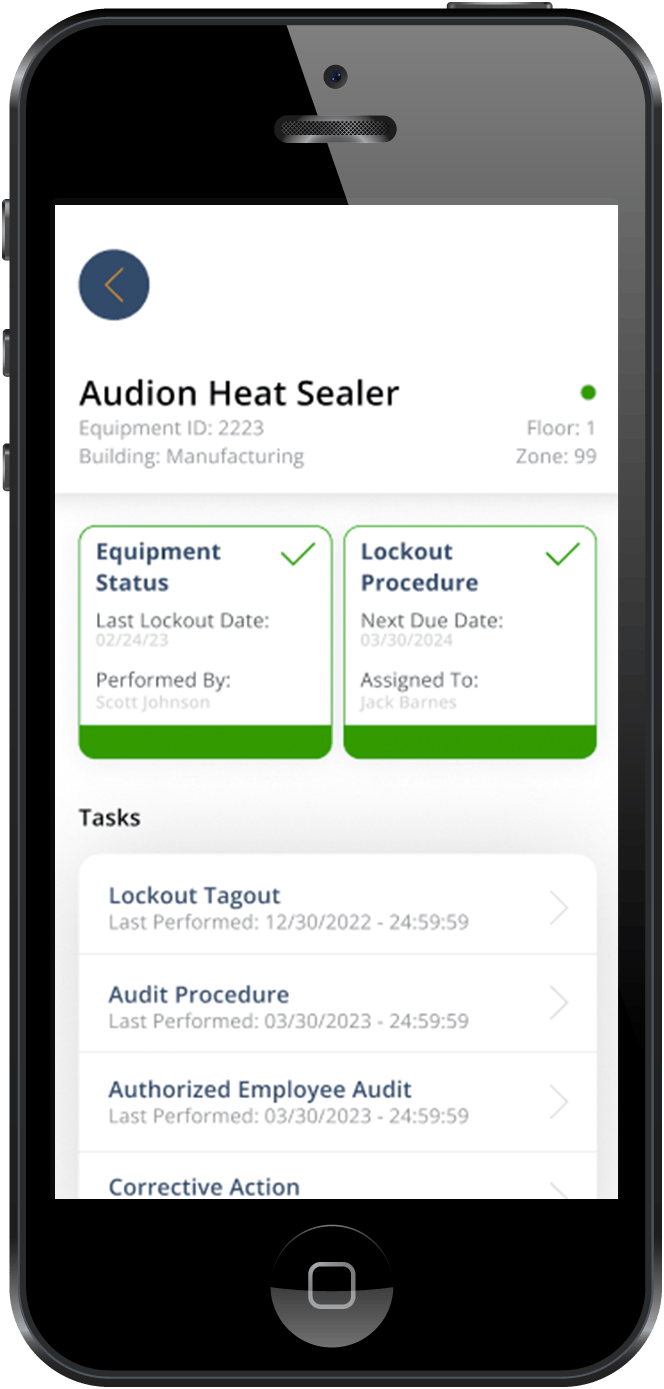

Building individual procedures for each piece of equipment can be a lengthy, tedious process. However, Smart Safety Pro’s lockout tagout software can simplify this process through the procedure builder feature. Building LOTO procedures with software is a simple and time-efficient process that can bring you one step closer to safety and compliance.

For guidance in developing effective lockout tagout procedures for each piece of equipment, see our article here: A Step By Step Guide to Creating Reliable Lockout Tagout Procedures.

Failing to train workers in lockout/tagout

Compliance Requirement: Per the standard, employers are responsible for ensuring that all staff members have a basic understanding of lockout tagout and receive sufficient training to fulfill their roles. Employees fall into one of three training groups outlined below.

-

- Authorized employees: This group includes those responsible for actually performing servicing and maintenance lockout tagout procedures. These workers need in-depth training that covers the purpose of lockout tagout, recognition of hazardous energy sources, proper lockout tagout procedures, and the importance of following safety protocols.

-

- Affected employees: This group includes those who operate the machinery being worked on or who work near equipment requiring LOTO procedures. Because their work would be impacted by lockout tagout, they must be trained on the risks associated with hazardous energy sources and know not to interfere during servicing.

-

- Other employees: This group includes all other employees. In a work environment that contains hazardous energy sources, it is vital that all employees have at least a basic understanding of the purpose of lockout tagout along with its function.

Common Employer Mistake: Many lockout tagout violations stem from employers who fail to provide adequate training. This may include generic training, in-frequent training, or no training at all. Regardless, lack of training makes the business vulnerable to fines, worker injuries, and improper care of assets.

Strategy for Compliance: Start by developing a training program that is tailored to the organization and its lockout tagout procedures. Then, provide comprehensive training to all employees. Training should be conducted at least annually by safety experts and include examples, hands on experiences, questions, and assessments.

An additional strategy for compliance is using lockout tagout software. Smart Safety Pro’s software offers an online knowledge base that can serve as a training refresher for workers as well as keep track of the training they have received. This way, only authorized employees who have received sufficient training can facilitate lockout tagout procedures.

For tips and best practices on developing a thorough lockout tagout training program, see our article here: Strategies for Preventing Workplace Injuries with Lockout Tagout Procedures.

Failing to conduct periodic inspections

Compliance Requirement: As established by OSHA, periodic inspections of each energy control procedure must be conducted at least annually. This is to ensure that the energy control procedures are being implemented properly and that employees are familiar with how to perform these procedures. Inspections should be conducted by competent individuals to ensure compliance with established procedures and identify any deficiencies or non-compliance issues.

Common Employer Mistake: There are 2 main ways that employers fall short in this area and receive a lockout tagout violation: neglecting inspections or lack of documentation. Employers that lack a set inspection schedule, willfully choose not to conduct inspections, or who have faulty documentation are subject to receiving a citation for this lockout tagout violation.

Strategy for Compliance: To avoid a lockout tagout violation for this requirement, establish a schedule for regular inspections of lockout tagout procedures, equipment, and documentation. Additionally, implement inspection protocol. Doing these 2 things can help organizations identify deficiencies, ensure compliance, pinpoint hazards, and reduce the likelihood of workplace accidents.

Traditionally, workers would have to manually record dates, file paperwork, and schedule inspections. However, technology has simplified this process. With lockout tagout software, companies can now enjoy automated scheduling, secure documentation, and immediate access to records. For companies seeking to improve their scheduling and documentation, investing in lockout tagout software is a proactive strategy for compliance.

Failing to establish a lockout/tagout program

Compliance Requirement: In order to be compliant with the lockout tagout standard, companies are required to develop and implement a formal lockout tagout program that includes written policies, procedures, training, and documentation.

Common Employer Mistake: Some workplaces lack written procedures, fail to communicate their program to employees, or neglect to establish a formal lockout tagout program altogether, resulting in ad-hoc procedures and inconsistent practices.

Strategy for Compliance: In an effort to avoid non-compliance, employers should establish clear policies and procedures, along with providing ongoing program oversight. As part of this, ensure that the program is communicated to all employees and stakeholders and is consistently applied across the organization.

For those wanting more information about building or improving a lockout tagout program, see our article here: A Step By Step Guide to Creating Reliable Lockout Tagout Procedures.

Failing to follow the sequence of lockout/tagout

Compliance Requirement: In order to remain compliant, organizations must establish a clear sequence of steps for conducting lockout tagout procedures, including isolation of energy sources, application of locks and tags, and verification of de-energization. Employees need to be trained on the correct sequence and ensure that procedures are followed consistently to prevent accidents or injuries.

Common Employer Mistake: Employers most commonly get cited for this violation due to missing steps in their procedures or failing to verify that their workers are following through on each step.

Strategy for Compliance: Compliance can be achieved and maintained through providing detailed procedural guidance, emphasizing the importance of sequence adherence, and certifying that employees are following a clear sequence of steps for LOTO procedures.

Additional help can come through the use of lockout tagout software, which includes step-by-step LOTO procedures designed by the company. When used, the software logs the user along with any actions they take, making it simple to recognize any skipped steps or ill-performed procedures.

Failing to protect workers during group lockout/tagout operations

Compliance Requirement: For compliance, all workers in a group lockout tagout operation must be able to “affix a personal lockout or tagout device” to a group lockout device. On top of that, employers should ensure adequate communication, coordination, and supervision are provided to protect workers during group lockout tagout activities.

Common Employer Mistake: Employers sometimes make group lockout tagout operations difficult or even impossible due to inadequate communication, supervision, training, or group lockout devices. If there isn’t anything that workers can affix a lock to during a group lockout tagout procedure, a citation is sure to come.

Strategy for Compliance: Managers can protect workers during group lockout tagout operations by implementing effective communication protocols, providing group LOTO training, and making sure that workers are able to affix a lock to a group lockout device

For more information about navigating group lockout tagout, see 1910.147(f)(3).

Failing to identify all energy sources and/or failing to lockout all disconnect sources

Compliance Requirement: According to 1910.147(b), an “energy source” includes anything that is considered a source of electrical, mechanical, thermal, hydraulic, chemical, pneumatic or other energy. Therefore, companies must conduct a thorough assessment to identify all energy sources, even those that are disconnected. Then, they must ensure that all energy sources are properly isolated and locked out to prevent unexpected energization during maintenance or servicing activities.

Common Employer Mistake: Employers may receive a lockout tagout violation as a result of incomplete identification of their energy sources or failure to lock out all sources.

Strategy for Compliance: To steer clear of a lockout tagout violation, organizations should conduct thorough energy source assessments, utilizing standardized lockout devices to properly isolate and de-energize these energy sources.

Failure to notify other employers

Compliance Requirement: In multi-employer workplaces, employers must communicate and coordinate lockout tagout activities to ensure the safety of all workers involved. This means that any other employers or contractors working on shared equipment or facilities must be notified about lockout tagout procedures, potential hazards, and any necessary precautions.

Common Employer Mistake: This common employer mistake simply comes down to lack of communication and failure to coordinate. It is worthy of a lockout tagout violation, because failure to notify other employers about lockout tagout procedures can result in confusion, conflicts, and increased safety hazards.

Strategy for Compliance: Lockout tagout violations for failure to notify other employers can be avoided by establishing communication protocols, documenting coordination efforts, and keeping one another updated.

To learn more about the requirement for lockout tagout operations involving multiple employers, see the OSHA standard 1910.147(f)(2).

Abusing the “servicing and tool changes” exception

Compliance Requirement: The Control of Hazardous Energy (Lockout/Tagout) safety standard applies to all normal operations. This means that any time an employee must bypass a safety device or guard or put any part of their body into a danger zone, they are required to conduct lockout tagout procedures. There is an exception to this rule; however, it only applies if the activity in question:

- Is minor

- Occurs during normal production/operations

- And is considered routine, repetitive, and integral (along with other protective measures being taken to safeguard the worker).

To remain compliant, be familiar with the 3 requirements above and ensure that the exception is applied only to tasks that meet that specific criteria. Additionally, make certain that appropriate preventative measures are in place to protect workers from hazardous energy sources.

Common Employer Mistake: Some employers may improperly use the “servicing and tool changes” exception by trying to apply this exception to servicing/maintenance jobs that are outside normal production operations. Others have run into issues due to the employer and OSHA having different stances on what constitutes “routine, repetitive, and regular.”

Strategy for Compliance: To bypass the mistakes listed above and avoid a lockout tagout violation, employers should take time to carefully read and understand the “servicing and tool changes” exception. Then, they must seek to implement it only when appropriate. If there is doubt about if an activity qualifies, don’t apply this exception to lockout tagout procedures.

For further clarification about this lockout tagout violation, see section 1910.147 (a) to read about when the lockout tagout standard applies and 1910.147 (a)(2)(ii)(b) to read about the exception regarding minor servicing activities.

Failing to manage shift change

Compliance Requirement: Shift changes present unique challenges for lockout tagout procedures, as incoming and outgoing workers must effectively communicate and transfer control of locked-out equipment. To best deal with this, develop procedures for managing shift changes involving locked-out equipment, including communication protocols, transfer of control procedures, and verification of lockout tagout status. Train incoming and outgoing workers on their roles and responsibilities during shift changes to prevent gaps in safety procedures.

Common Employer Mistake: Receiving a lockout tagout violation for failed shift changes can come simply because an employer failed to foresee that a particular lockout tagout procedure would take longer than a single shift. This lack of planning and preparation can result in workers leaving their locks attached to a piece of machinery or equipment at the end of their shift, leading to unauthorized removal of tags by the next employees who come in.

Strategy for Compliance: To prevent a lockout tagout violation for failed shift changes, establish shift change protocols and conduct training for all involved personnel. An increased level of awareness from all personnel will help reduce the likelihood of an issue between shifts.

Types of violations and their associated penalties

*Note: These values may change over time with any adjustments made by the organization to account for inflation and other factors.

Other Than Serious Violation – This phrase refers to the violations that are related to health and safety but that are very unlikely to result in a fatality or severe physical harm to an individual. As of January 2023, financial penalties for this category averaged between $14,502 and $15,625 per violation.

Serious Violation – A violation is considered “serious” if there is a high chance of death or severe physical harm that could occur to a person as a result of the infringement. In these cases, it is understood that the employer was aware of or should have known the nature of the situation. Fines for serious violations are capped at $15,625.

Willful Violation – These violations are determined to be ones the employer has knowingly and intentionally been involved in. Employers fall into this category if they have knowingly condoned actions or circumstances that create a hazardous environment for their workers, whether through intentional action or neglectful management of an identified problem. Employers who are found willfully violating OSHA safety standards will face civil penalties that can be as large as $156,259 per violation.

Failure to Abate – These violations are given to employers who procrastinate correction. Companies that receive a re-inspection and have not fixed a previously-cited violation will be fined a maximum of $15,625 for every day that the issue is not resolved past the abatement date. Generally, this timeline is limited to 30 days.

Repeat Violation – Repeat violations are given to employers who have been cited for violating a rule, standard, or regulation are found committing a very similar violation upon re-inspection. To distinguish these from ‘Failure to Abate’ cases, repeat violations can only be given after the initial citation is finalized. Therefore, any citations that are currently under review cannot become repeat violations. However, for those to which this applies, fines can be as great as $156,259 for each violation.

Conclusion

Addressing the top 10 most frequently cited lockout tagout violations requires a proactive approach to workplace safety. By developing and implementing comprehensive lockout tagout programs, providing thorough training, conducting regular inspections, and fostering a culture of safety, employers can minimize risks, protect workers, and ensure compliance with regulatory requirements.