This article explores 4 benefits of lockout tagout and explains why having a LOTO program is a worthwhile safety measure to invest in.

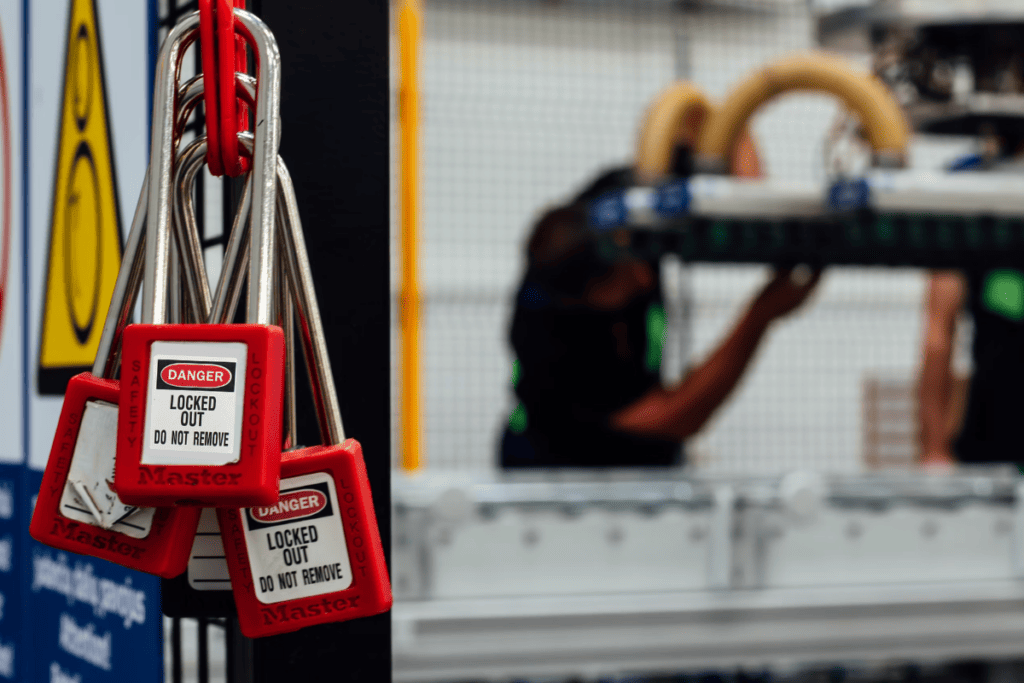

Man Performing Lockout Tagout Procedures On a Machine

Understanding Lockout-Tagout (LOTO)

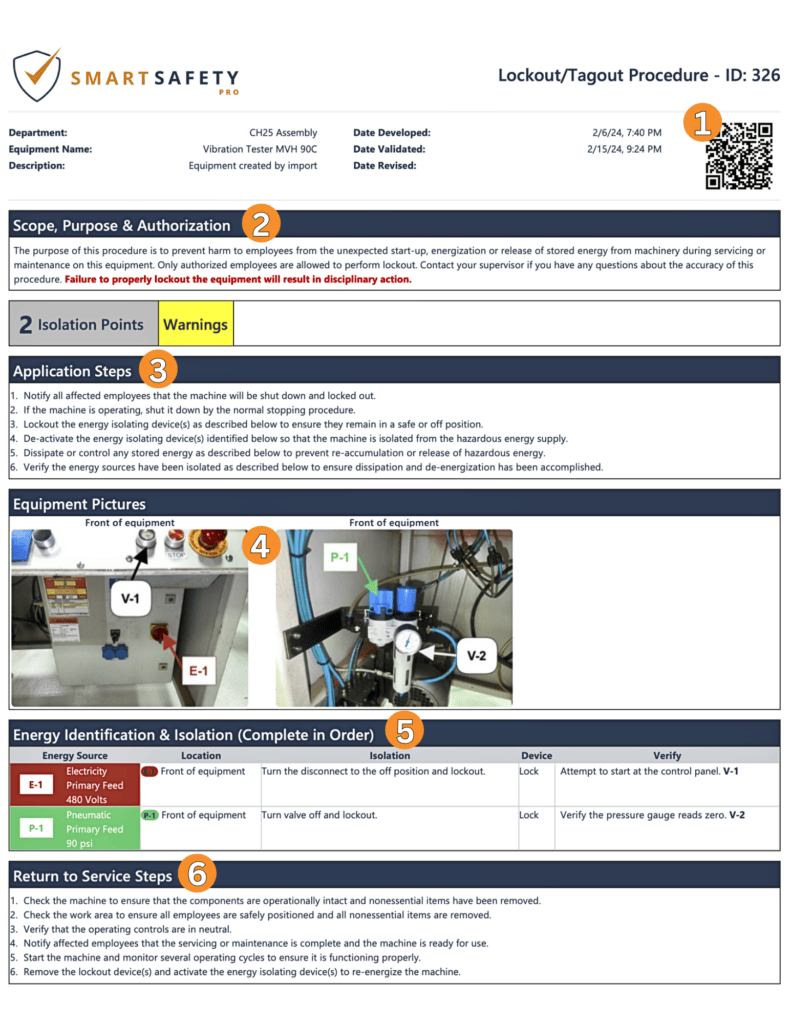

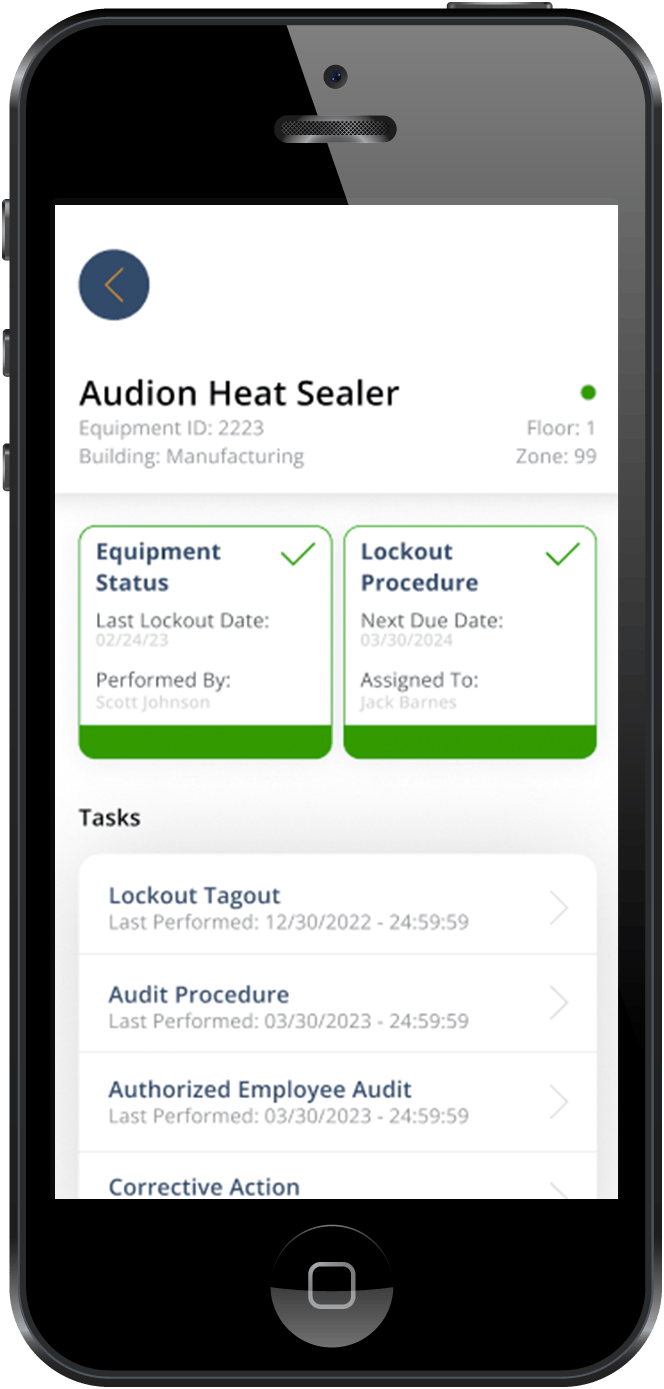

Lockout-Tagout is a comprehensive safety procedure designed to safeguard workers from the hazards associated with the sudden energization or startup of machinery or equipment during maintenance or servicing. The term “lockout” refers to physically isolating and locking the energy-isolating device to prevent the release of hazardous energy, while “tagout” involves attaching a warning tag to indicate that the equipment must not be operated. This dual approach creates a visible and tangible barrier to potential dangers, providing a layer of protection for those working on or around the equipment.

The Primary Purpose of Lockout Tagout

Lockout tagout has 4 main purposes and functions that also serve as benefits. Lockout tagout is meant to help with:

- Preventing Accidents and Injuries

- Maintaining Regulatory Compliance

- Protecting Lives and Property

- Encouraging Communication and Collaboration

Though it can be a timely process to manage a LOTO program and properly perform lockout tagout procedures, these 4 purposes help demonstrate why it is such a worthwhile safety measure.

To further convey the value of loto procedures, we will now do a deep dive into each of these 4 purposes, discussing how the purpose is accomplished and why it can be helpful for companies and organizations.

1. Preventing Accidents and Injuries

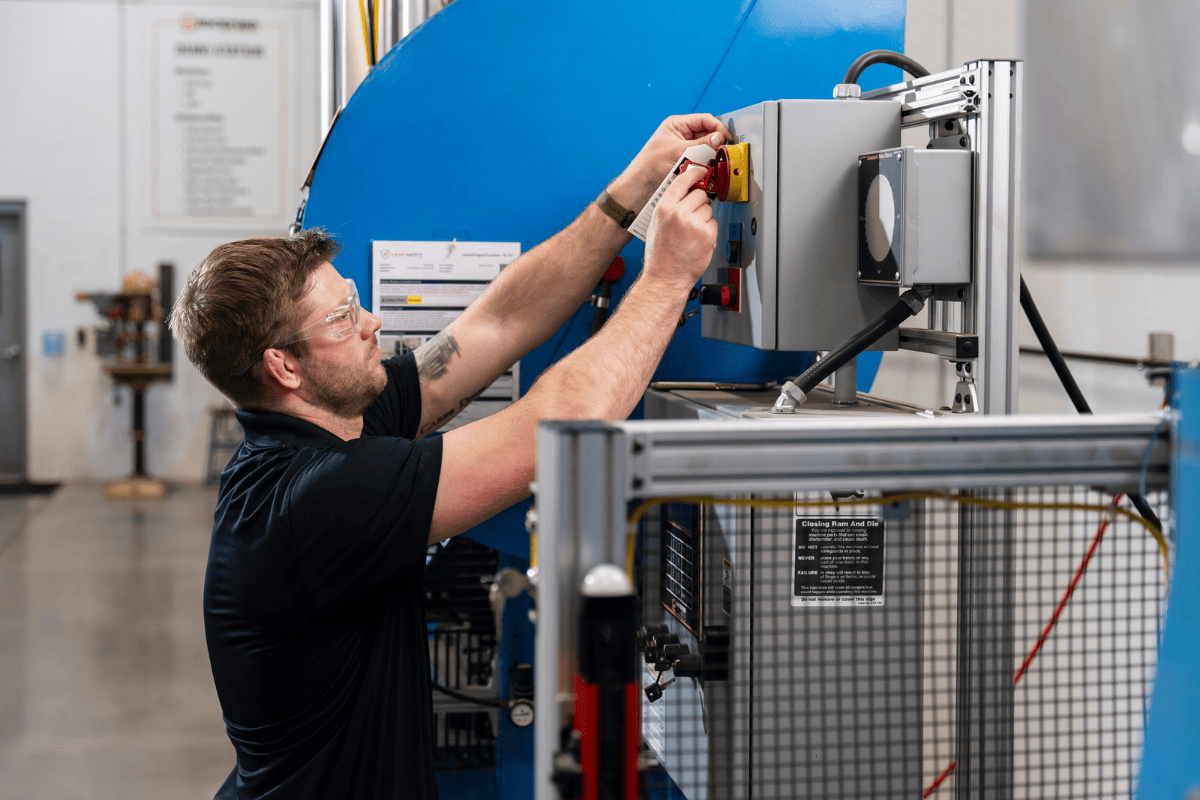

Lockout tagout is a highly effective tool for preventing accidents and injuries, making it a safety measure that is well worth the time and energy involved. How you might ask? Well, lockout tagout helps safeguard workers from unexpected energization of machinery by keeping the equipment securely shut down for a temporary period of time. Often it is used so that workers can safely engage in tasks such as repairs, adjustments, or cleaning. With a lock to physically secure the machine and a tag with important information, workers are able to conduct the necessary jobs on equipment that is in a safe, deactivated state, minimizing the risk of harm.

It is much easier to prevent an accident through proactive measures than to deal with the consequences and aftermath of a serious or even fatal incident. After all, unexpected machine energization can lead to injury or even death of workers. Not only does this present immediate issues, but there can be ripple effects as well.

OSHA states that, “Workers injured on the job from exposure to hazardous energy lose an average of 24 workdays for recuperation.”

Therefore, neglect of lockout tagout procedures and resultant employee injury/death can lead to loss of operational efficiency, high costs associated with worker’s comp/hospital bills, legal fees, reputation damage, and overall loss of trust and security among company workers. With lockout tagout, these unfortunate circumstances can be avoided.

2. Compliance with OSHA Standards

Another clear benefit to performing lockout tagout procedures is the fact that they are a way to check for compliance with safety standards. In the United States, the Occupational Safety and Health Administration (OSHA) is the governing body that establishes and regulates standards for workplace safety.

OSHA has established particular guidelines related to LOTO in their standard 29 CFR 1910.147 The Control of Hazardous Energy (Lockout Tagout). In this standard, employers are mandated to develop, implement, and enforce an energy control program that includes comprehensive LOTO procedures. Therefore, compliance with these standards is not just a best practice but a legal requirement, and failure to adhere to them can result in severe consequences, including fines and legal actions.

When it comes to OSHA, the fines and violations are not created equal. The type of violation that is given for an OSHA standard infraction and its associated fine are subject to the severity of the issue. However, all OSHA violations do come with a cost, and that cost can be pretty great.

Just to provide reference, here is a startling statistic.

“The U.S. Occupational Safety and Health Administration charged businesses $132.3 million for violations of its 10 most cited regulations in 2023” and $21.7 million of that was specifically for lockout tagout violations. (MSC Direct)

So what kinds of violations are there anyways? The types of OSHA violations that can be received include:

- Other Than Serious Violation

- Serious Violation

- Willful Violation

- Failure to Abate

- Repeat Violation

To learn more about each of these kinds of violations, the fines that go with them, and the top 10 most common lockout tagout mistakes, see our article here. It helps provide a closer look at the real repercussions of not taking lockout tagout seriously. That way, you can focus on avoiding these negative consequences for noncompliance and instead reap the benefits of compliance.

By properly conducting lockout tagout procedures, companies can enjoy the peace of mind that comes from avoiding non-compliance fees and violations. Not to mention, they avoid financial penalties that can reach thousands or even hundreds of thousands of dollars. Lockout tagout makes it much more simple to comply with legal safety regulations. For this reason, it is a worthwhile investment of time and energy.

3. Protecting Workers’ Lives and Well-being

Lockout tagout serves as the frontline safety measure against hazardous energy or accidental machine start up for workers. Because of this, it is a vital aspect of workplace safety.

The truth is, industrial machinery often involves high levels of energy that, if not properly controlled during maintenance, can pose severe threats to worker safety. Lockout-tagout procedures provide physical protection to workers, by significantly decreasing the likelihood of an accident occurring. Procedures also provide mental and emotional protection to workers by helping them feel safe and comfortable in their workplace.

In fact, OSHA records show that “Compliance with the lockout/tagout standard prevents an estimated 120 fatalities and 50,000 injuries each year.”

This statistic helps demonstrate just how impactful lockout tagout procedures can be in providing safety. However, the value of loto procedures doesn’t end there. Lockout tagout not only helps protect life, but it also helps protect operational efficiency as well. You see, trained workers help maximize efficiency through their knowledge and experience. Therefore, injury or loss of life due to a workplace accident results in not only the loss of life, but also loss of expertise. This leads to either a shortage of workers or the need to quickly find and train new workers on company specific procedures. And so, prioritizing lockout tagout can serve the best interests of both the workers and their employer.

4. Facilitating Clear Communication

Clear communication is essential in any workplace, especially when it comes to safety. However, communication isn’t always verbal. Particularly in buildings with loud machinery or many workers, the locks and tags used in lockout tagout can serve as a visual and unmistakable signal to all personnel that specific equipment is undergoing maintenance and should not be operated. This visual communication from the tag helps prevent misunderstandings and reinforces a culture of safety throughout the organization.

In fact, OSHA has offered a recommended system for using colored tags, locks, and signage to convey specific visual meanings to viewers. The OSHA recommended system for colored LOTO tags is as follows:

- Red Tags: Danger – Do Not Operate

- Yellow Tags: Caution – Out of Service

- Orange Tags: Warning – Information Only

- Fluorescent Orange/Orange-Red Tags: Biological Hazard – Beware

While it is not mandated to use this coloring system, it can be helpful to have a standardized coloring system with designated meanings and purposes. For more information about the meaning behind colored loto tags, see our article here!

Not only can the equipment (colored locks and tags) for lockout tagout facilitate clear communication within an organization, but the very process of performing lockout tagout procedures can help as well. One of the crucial first steps in loto procedures is notifying all affected employees that equipment is going to be shut down and worked on. This means that it is expected for workers performing loto to clearly convey their intentions and action plan with anyone whose work would be affected by the machine shut down and deenergization. This key step in lockout tagout helps promote active communication.

While lockout tagout is often an individual job, there are times when group lockout tagout is necessary. Particularly in those situations, the nature of the job leads to increased collaboration and teamwork. Since there are multiple people working on the equipment, everyone has to rely on one another and voice their thoughts in order to maintain safety.

It is evident that there are many aspects of lockout tagout, such as colored tags, the need to notify affected employees, and group lockout tagout, that support and promote clear communication among employees. This natural benefit of lockout tagout makes it a worthwhile endeavor.

Conclusion

Lockout tagout is a precautionary safety measure used in the workplace to actively promote safety and prevent incidents. While there are many benefits to using this process, there are 4 main reasons to conduct lockout tagout procedures. First, it is a tool for reducing the likelihood of accidents or injuries. Second, it is a way for companies to check their compliance with established regulations. Third, it is a systematized way of protecting worker lives. And lastly, lockout tagout encourages clear communication and collaboration among employees. For these reasons, and their associated benefits, lockout tagout is a safety measure that is well worth the time and energy.