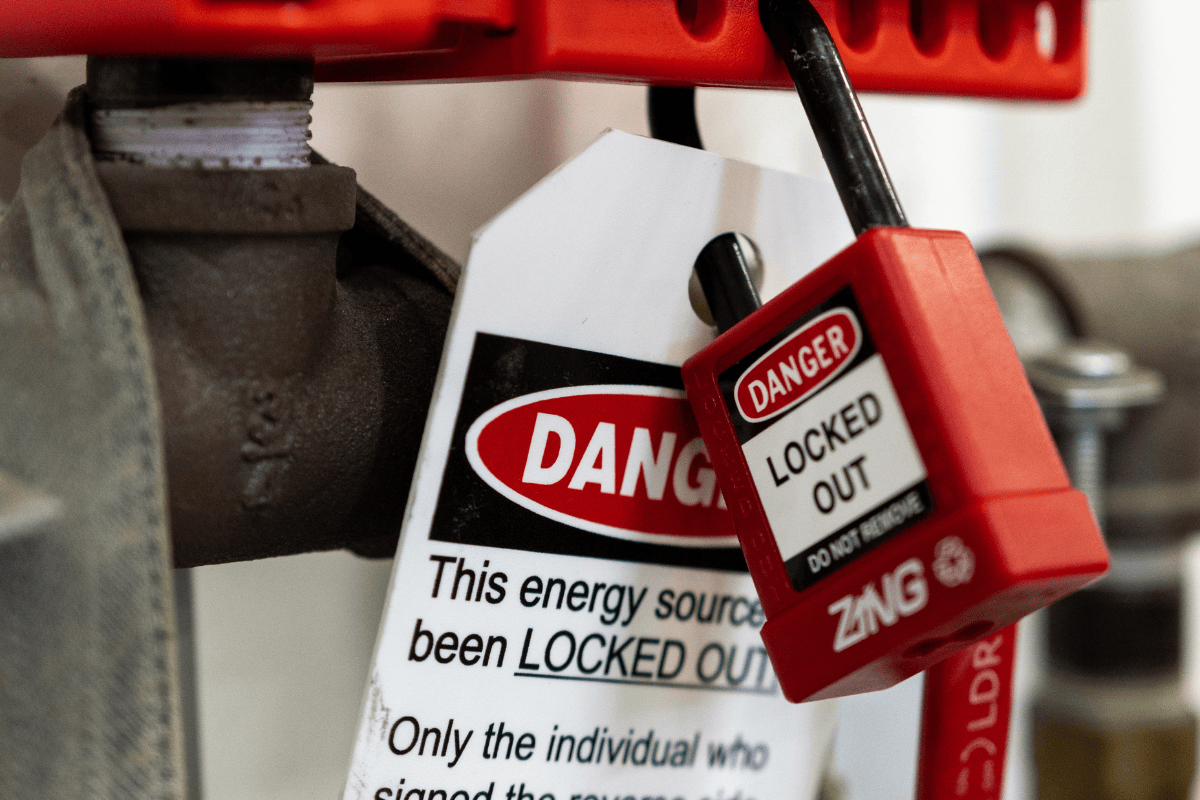

In every workplace, safety procedures are put in place to protect employees from harm, reduce accidents, and ensure compliance with regulations. However, even with well-documented safety protocols, many workers fail to follow them consistently. Understanding the reasons behind this behavior is key to creating a stronger safety culture and reducing workplace accidents.

In this article, we’ll explore some of the common reasons why people don’t always follow LOTO safety procedures and what can be done to address these issues.

7 Common Barriers to LOTO Safety

While there are an abundance of reasons that employees don’t always follow through with LOTO safety procedures, the following sections will highlight the 7 most common hinders to procedure completion:

- Lack of Understanding or Training

- Perceived Time Constraints or Pressure

- Overconfidence/Familiarity With the Job

- Lack of Consequences or Accountability

- Inconvenience or Difficulty Following Procedures

- Poor Communication From Management

- Lack of Employee Engagement or Buy-In

1. Lack of Understanding or Training

The Problem: One of the most common reasons workers don’t follow lockout tagout safety procedures is a lack of proper training or understanding of those procedures. Without clear, thorough instruction, employees may not know how to correctly implement safety protocols, or they may misunderstand their importance. This is why developing lockout tagout procedures that are detailed and equipment-specific is so important.

Why It Happens:

- Inadequate training programs or rushed onboarding processes can leave employees confused about safety expectations.

- Employees might not understand the purpose behind certain procedure steps, their importance, or potential repercussions for negligence.

- Lack of experience seeing a procedure be performed or doing it themselves can leave workers feeling unsure about next steps during the process.

Solution:

- Provide comprehensive training: Ensure that all employees receive detailed and clear instruction on safety procedures during their onboarding process. Use hands-on demonstrations, practical examples, and real-life scenarios to help workers understand the purpose and necessity of each procedure.

- Give workers tools for success: Make sure that employees have resources they can rely on. This might mean easy access to LOTO safety procedures, a supervisor to ask questions to, or handbooks with the most recent safety regulations regarding lockout tagout. (Think OSHA 1910.147 or ANSI Z244.1)

- Ongoing education: Regular refresher training can reinforce safety principles and keep employees up-to-date with any new safety measures or regulations. We recommend that lockout tagout refresher training be offered at least annually.

How Software Can Help:

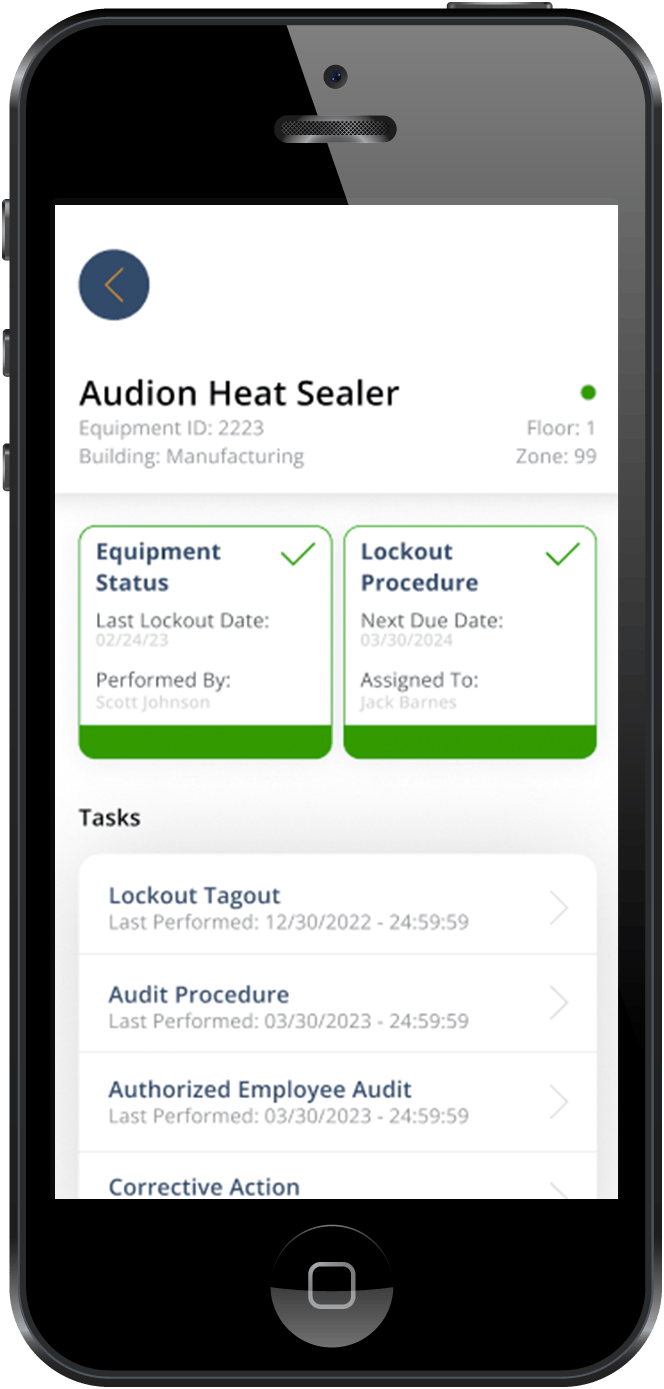

LOTO software provides workers with digital access to detailed, step-by-step instructions for each lockout procedure, including equipment-specific requirements, energy isolation points, and safety steps. It can also include visual aids like diagrams and videos that make complex procedures easier to understand. Not only that, but our lockout tagout software includes a knowledge base with training materials that can be used to teach workers about the job and provide refreshers.

Benefits of Using Software:

- Interactive training: Software-based training modules and tutorials can offer a hands-on learning experience, ensuring that employees fully grasp how to perform each procedure. Plus, these training modules can be reviewed time and time again.

- Clear, real-time guidance: Our software requires users to verify that they’ve completed a step before moving on to the next one. By following these digital prompts, workers can easily understand each step of the process, reducing the risk of errors caused by misunderstanding or lack of training.

2. Perceived Time Constraints or Pressure

The Problem: Workers often skip or cut corners on safety procedures because they feel rushed or pressured to meet deadlines or production goals. In high-pressure environments, safety can be seen as an inconvenience that slows down productivity. However, skipped steps can lead to disastrous outcomes such as fatal accidents, injured personnel, or large fines for OSHA violations. Because of these hazardous potential outcomes, it is vital to help workers prioritize following LOTO safety procedures and making time for them.

Why It Happens:

- Tight deadlines and high output expectations can cause employees to feel like they don’t have enough time to follow every step of a safety process.

- Supervisors or managers may inadvertently encourage unsafe shortcuts in the pursuit of efficiency or faster results.

Solution:

- Promote a culture of safety over speed: Management must emphasize that safety is the top priority and never something to be sacrificed for the sake of speed. Communicate that following safety protocols is part of being efficient. Additionally, focus on setting clear expectations, being an example, and positively reinforcing those who follow LOTO safety procedures.

- Allow sufficient time for tasks: When planning projects or production schedules, include adequate time for employees to safely complete their tasks. Ensure workers don’t feel they must choose between safety and meeting deadlines.

How Software Can Help:

With Smart Safety Pro software, users can generate specific, complete lockout tagout procedures within MINUTES! This means that setting up a lockout tagout program takes much less time. Not only that, but using the software to perform LOTO safety procedures can streamline the lockout process by automating documentation, providing checklists, and integrating QR codes for fast equipment identification. By simplifying the lockout process, it saves time while ensuring safety protocols are adhered to.

Benefits of Using Software:

- Minimizes delays: Automated checklists and simplified workflows reduce the perceived time burden, making it easier for employees to incorporate safety steps without feeling rushed.

- Encourages consistency: The inspection software ensures that all necessary steps are followed, eliminating shortcuts and ensuring compliance, even in high-pressure situations.

- Improved efficiency: Software can improve efficiency in writing lockout tagout procedures, performing LOTO, completing reports, and retrieving data.

3. Overconfidence or Familiarity with the Job

The Problem: Experienced employees may become overconfident in their abilities, leading them to ignore safety procedures they feel are unnecessary. Familiarity with routine tasks can result in complacency, where safety protocols are seen as irrelevant. Workers who have been with the company for a significant time may be more prone to struggle with changes in procedures or adopting new safety practices. These team members may need extra attention and support to recognize the significance of each step.

Why It Happens:

- After performing the same tasks repeatedly, employees may believe they can do the job “safely” without following all the prescribed steps.

- A sense of complacency develops, especially if the employee has never experienced or witnessed an accident while cutting corners.

- Workers assume they know enough about the job to bypass certain steps, especially if those steps seem redundant or overly complex.

Solution:

- Reinforce safety importance regularly: Regularly remind even the most experienced workers about the risks of ignoring safety procedures. Share real-life stories of accidents that resulted from complacency to drive home the message.

- Rotate tasks or roles: Consider rotating workers’ tasks to keep them engaged and mindful of safety procedures, helping to break the monotony that can lead to complacency.

- Involve Experienced Workers in Trainings: Ask the more experienced workers to help demonstrate LOTO safety procedures step-by-step during a training, ensuring that they perform it according to company policy. This will encourage them to practice performing it properly and help them feel recognized for their knowledge.

How Software Can Help:

Smart Safety Pro’s software offers real-time tracking and monitoring of safety compliance, ensuring that even experienced workers follow every step of the procedure. Digital reminders and alerts help prevent complacency by emphasizing the importance of following each step every time, regardless of experience level.

Benefits of Using Software:

- Promotes consistent safety habits: By providing real-time guidance, the software ensures that no step is skipped, reinforcing the importance of every procedure—even for those who are familiar with the equipment.

- Reduced risk of human error: The system acts as a safety net, ensuring that workers complete all necessary steps, regardless of overconfidence or complacency.

4. Lack of Consequences or Accountability

The Problem: When employees see that others who ignore safety procedures don’t face consequences, they are more likely to disregard them as well. A lack of enforcement from management sends the message that safety rules are flexible or optional. This can be problematic in spreading malpractice. Therefore, encourage supervisors to be engaged with their workers and aware of work quality.

Why It Happens:

- Supervisors may overlook violations if no accidents have occurred, or they may prioritize production over strict enforcement of safety rules.

- Employees might feel that management doesn’t genuinely care about safety if infractions are regularly ignored.

- Uninvolved managers and supervisors may be oblivious to worker negligence regarding safety and therefore not provide the needed correctional structure.

Solution:

- Establish and enforce consequences: Create a clear disciplinary policy for not following safety protocols, and ensure that managers consistently enforce it. Make it clear that safety violations will have real consequences. Afterall, violations can result in hefty fines for companies. Workers need to understand that there are repercussions for their behavior.

- Encourage accountability at all levels: Promote a safety culture where everyone is responsible for adhering to procedures and holding each other accountable. Recognize and reward safe behavior to encourage compliance.

How Software Can Help:

LOTO tags already encourage accountability by telling who was working on a particular piece of machinery, however, lockout tagout software can take it a step further. LOTO software tracks user activity, including who initiated a lockout, what steps were followed, and when locks were applied and removed. This creates a detailed digital record, making it easier to monitor compliance and identify any deviations from safety procedures. These logs can be used to reward those who faithfully follow LOTO safety procedures and punish those who willfully choose not to comply.

Benefits of Using Software:

- Increased transparency: Supervisors can track compliance in real-time and ensure that every step is properly followed, promoting a higher level of accountability.

- Consistent enforcement: With software-based tracking, managers can more easily enforce consequences for non-compliance while rewarding workers who follow protocols, helping to reinforce a culture of accountability.

5. Inconvenience or Difficulty Following Safety Procedures

The Problem: Some LOTO safety procedures may be seen as inconvenient, complicated, or difficult to follow. When safety protocols seem overly complex or time-consuming, workers may be tempted to take shortcuts. You want to encourage and incentivize safety, so it is worthwhile to get to the bottom of things when it comes to this issue.

Why It Happens:

- Procedures may not be designed with the worker’s actual experience in mind, resulting in cumbersome steps or unclear instructions.

- Workers might feel that there is insufficient equipment for performing LOTO safety procedures or have to search for available equipment, making it more difficult to prioritize.

Solution:

- Simplify and streamline procedures: Review safety protocols to ensure they are practical, clear, and easy to follow. Seek feedback from workers to identify any steps that could be simplified. Having these conversations will open the door for improved procedures and overall safety.

- Provide appropriate safety equipment: Ensure that there is a sufficient supply of locks, tags, and other lockout tagout equipment for performing procedures. Also provide a designated area for workers to put their locks and tags. This way, workers have the tools they need and know exactly where to find it. Regularly check that equipment is well-maintained and that workers are properly trained in its use.

How Software Can Help:

LOTO software simplifies complex lockout procedures by automating repetitive tasks and guiding workers through each step with on-screen prompts and reminders. It eliminates the need to manually fill out forms or memorize complicated procedures. With Smart Safety Pro software, workers can perform procedures in just a couple of minutes, making it something that is very doable to incorporate into their workflow.

Benefits of Using Software:

- Ease of use: Employees can access detailed procedures instantly, scan QR codes for equipment-specific instructions, and follow on-screen guides to reduce confusion or difficulty when performing LOTO. Additionally, it is very easy for admins to make edits to procedures, allowing them to be updated and clarified over time!

- Reduces procedural friction: The software makes following safety steps more convenient by streamlining the process, ensuring workers are less likely to view procedures as overly complex or time-consuming.

6. Poor Communication from Management

The Problem: If management does not clearly communicate the importance of safety procedures, workers may view them as secondary to other goals. Inconsistent messages about safety can create confusion and lead to lax practices. Ultimately, management is responsible for conveying expectations, establishing the culture, and communicating proper safety procedures.

Why It Happens:

- Safety may be discussed during training but not reinforced in day-to-day operations.

- Mixed signals from leadership, such as emphasizing productivity over safety, can lead to unsafe practices.

Solution:

- Lead by example: Managers and supervisors must demonstrate their commitment to safety by consistently following and enforcing safety protocols. Their actions will set the tone for the rest of the workforce.

- Maintain open lines of communication: Encourage workers to voice their concerns about safety, ask questions, and report any issues with procedures. Ensure that safety is a key topic in meetings and performance reviews.

How Software Can Help:

LOTO software promotes better communication between management and employees by centralizing safety procedures, incident reports, and compliance data. One cool feature of Smart Safety Pro software is that it doesn’t require wifi to update. This means that it can be used anytime, anywhere and that the other team members will be able to access the most recent data and reports. With this feature, supervisors can monitor LOTO activity in real time, providing support and feedback when necessary. This helps teams stay up to date, collaborate on jobs, and seamlessly share information.

Benefits of Using Software:

- Real-time collaboration: Managers and workers can communicate more effectively about lockout procedures, ensuring that any issues are addressed quickly and efficiently.

- Improved oversight: Management can easily monitor compliance, provide real-time guidance, and show commitment to safety through continuous support and reinforcement of safety procedures.

7. Lack of Employee Engagement or Buy-In

The Problem: If employees don’t see the value in following safety procedures or don’t feel invested in the company’s safety culture, they are less likely to comply. This lack of buy-in can be driven by poor morale, mistrust of management, or a failure to connect safety rules with personal well-being.

Why It Happens:

- Workers may feel disconnected from the company’s broader safety goals or see procedures as irrelevant to their daily tasks.

- A lack of trust between employees and management can lead to disengagement from safety efforts.

Solution:

- Involve employees in safety planning: Engage workers in safety-related decision-making and discussions about safety protocols. Involve them in creating or updating procedures. Their firsthand knowledge can lead to better, more practical solutions. Not only that, but their participation will foster a sense of ownership and accountability for safety outcomes.

- Foster a strong safety culture: Build a workplace culture where safety is viewed as a shared responsibility and where workers feel empowered to contribute. Recognize and reward teams for proactive safety measures and improvements.

How Software Can Help:

LOTO software actively engages employees by making safety protocols easier to follow, track, and understand. By providing intuitive tools and personalized guidance, workers are more likely to feel invested in the safety process and take ownership of their responsibilities.

Benefits of Using Software:

- Empowerment: Workers gain access to the information they need to confidently follow procedures, improving their engagement with safety protocols.

- Recognition and rewards: Software can track individual compliance, making it easier to recognize and reward employees who consistently adhere to safety guidelines, fostering a positive safety culture.

Conclusion

There are many reasons why workers might not follow safety procedures, from inadequate training and time pressures to complacency and poor communication. Understanding these underlying factors is crucial for creating an environment where safety is prioritized. By addressing these barriers and fostering a strong safety culture, organizations can significantly reduce the risk of accidents and ensure that everyone goes home safely at the end of the day.