Are you looking for the best lockout tagout software on the market? Lockout Tagout (LOTO) regulations are put in place to protect workers from the hazards associated with the unexpected energization or startup of machines and equipment during maintenance, servicing, or repair. In the United States, the primary regulatory authority for LOTO is the Occupational Safety and Health Administration (OSHA). The specific standards related to lockout tagout can be found in 29 CFR 1910.147, “The Control of Hazardous Energy (Lockout/Tagout).” A robust lockout tagout program is essential for ensuring the safety of workers during maintenance or servicing of equipment. Developing and maintaining an OSHA compliant lockout tagout program can be both challenging and time consuming, but good software can remove many of the challenging aspects of the program, and make the process MUCH faster. With so many different lockout tagout software programs on the market, selecting the right program might seem overwhelming. Let’s take a look at the most important features to consider when selecting lockout tagout software.

User-Friendly Lockout Tagout Software

User friendly lockout tagout software provides a positive and enjoyable experience for users. One of the most important factors to consider when searching for the best lockout tagout software is whether it is intuitive. Intuitive and easy to understand interfaces reduce the time and effort required for users to learn how to use the software. This is especially important in environments where users need to quickly adapt to new tools, or when the primary software users have occupational expertise in safety and maintenance, not IT or software.

The best lockout tagout software has a much higher adoption rate because it is user friendly. If lockout tagout software is easy to understand and meets user expectations, individuals are more likely to use it consistently and recommend that others do the same.

Mobile Procedure Builder

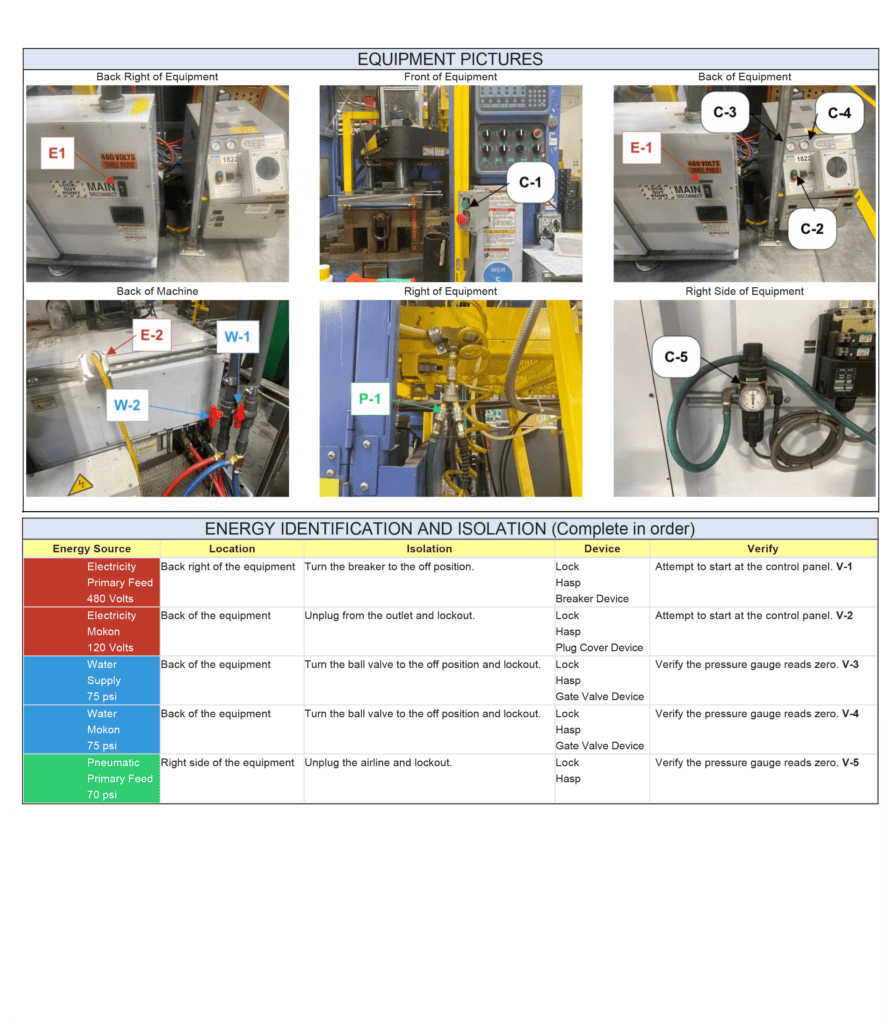

The best lockout tagout software includes a truly mobile procedure builder. A lockout tagout procedure is a document that contains a set of specific steps and verification methods that must be used to de-energize and shut down a machine or energy source. The lockout tagout procedure normally includes an image of each energy source that is annotated with arrows and tags. The tags correspond to specific energy isolation instructions and verification steps. All the images and instructions for a machine are compiled into a formal document called a procedure.

Traditional methods of building lockout tagout procedures include manually via word processing software, or with lockout tagout software. It can frequently take an hour or more to build a single procedure because the process involves taking pictures on a phone and writing down isolation and verification steps on paper, going back to a desktop and uploading the pictures, using photo editing software for image annotation, typing in the instructions, and compiling everything into a report. Lockout Tagout software can streamline many of the steps such as providing photo editing tools and a procedure report template to add the information to, but the process remains clunky and time consuming. Additionally, if the steps in a procedure change, it is likely that it will need to be recreated from scratch.

The best lockout tagout software offers a mobile procedure builder. A mobile procedure builder, such as the one included with Smart Safety Pro Lockout Tagout, reduces the time required to create a procedure from hours to minutes. A widget walks the user through the steps to add each energy source, offering drop-down menus for things like energy type, magnitude, feed, locking devices, and location. It provides text fields for the user to enter isolation and verification instructions. Finally, the user is prompted to take a photo of the energy source right from the mobile app. Once the photo is taken, on-screen arrows and tags are provided so that annotation can be done inside the app. The photo is saved and the energy source documentation is complete. Additional energy sources can be added until the documentation is complete. Upon completion, the procedure draft is ready for approval and a beautifully formatted report is auto-created and available for printing.

Creating a lockout tagout procedure from a mobile app is more accurate because the user is standing right in front of the machine and able to directly enter accurate information. When the process involves going into an office to use a computer, information can be lost or modified along the way. Additionally, the best lockout tagout software stores procedures inside the equipment record. In the event that a procedure needs to be modified, the process is as simple as scanning the equipment, editing the procedure, and reprinting it. The best lockout tagout software includes a mobile procedure builder because it is faster and more accurate than a split or manual process.

Audit Tools

The regular auditing of both procedures and employees is mandated by OHSA. Audits help organizations assess compliance with relevant regulations, identify areas for improvement, and ensure that employees are adequately trained and equipped to perform lockout tagout procedures. While specific audit requirements may vary based on local regulations, industry standards, and company policies, here are some general elements often included in LOTO audit requirements:

Written Program Review: Evaluate the organization’s written lockout/tagout program to ensure that it is comprehensive, up-to-date, and aligns with applicable regulations and standards (e.g., OSHA 29 CFR 1910.147 in the United States).

Procedure Documentation: Review lockout tagout procedures for specific equipment and machinery to ensure they are well-documented, accurate, and easily understood. Procedures should be available to authorized employees and reviewed periodically for updates.

Employee Training: Verify that employees involved in lockout tagout activities have received appropriate training. This includes understanding the energy control program, knowing how to use lockout tagout devices, and being aware of potential hazards.

Authorized Employee Identification: Confirm that only authorized employees are performing lockout tagout procedures. This may involve reviewing records of trained and authorized personnel.

Audit of Specific Lockout/Tagout Procedures: Conduct specific audits of randomly selected lockout/tagout procedures to ensure adherence to the established protocols.

As with any type of audit, documentation is key to ensuring audits were performed and understanding when they are due next. The best lockout tagout software contains an auditing module that tracks audit due dates and offers notifications when they are due, provides an area within the mobile app to complete the audit, and keeps a history of all audits with reporting capabilities. It will even reschedule the next audit according to the recurrence setting after an audit is performed. When the best lockout tagout software is used for managing audits, users no longer need to worry about remembering to schedule and perform audits, managing due dates, or written documentation surrounding audits. If OSHA or any other AHJ requests proof that audits were completed according to guidelines, this information is a button click away with an on-demand audit report.

Mobile Lockout Tagout Procedure Execution

Conventional lockout tagout programs rely solely on an authorized employees to follow the written steps of a lockout procedure. They trust that the employee followed all the steps properly but there is no real verification method. Additionally, the only way to know which machines are locked out is to walk around the facility and physically look for locks.

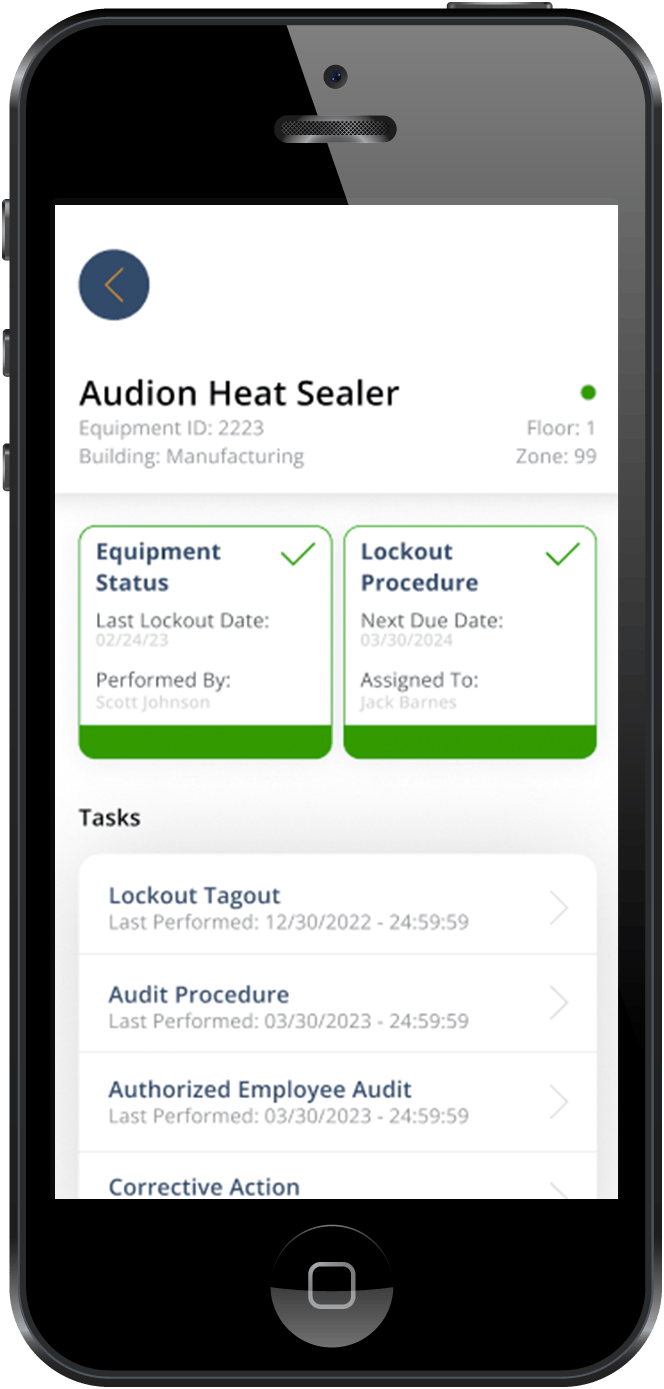

The best lockout tagout software overcomes these challenges. Smart Safety Pro Lockout Tagout software assigns a QR code to each procedure. The procedure is also transformed into a digital checklist that walks the authorized employee through the steps of performing the procedure. At each step the employee is presented with the annotated image of the energy source, the isolation instructions, and the verification steps. The authorized employee confirms in the app that each step was successfully completed. If a step cannot be completed, the lockout process is stopped and an issue is automatically created in the software. The best lockout tagout software uses these measures to verify that the lockout procedure is completed as written every time.

The best lockout tagout software also maintains an inventory of all equipment within a facility. Each equipment can be assigned a unique QR code. An equipment overview list with status is available within the lockout tagout mobile app, within the web-based program, or via reporting. Or, simply scan on an equipment QR code to open the equipment record and see current equipment status, last lockout date, last procedure audit date, and more.

Using the best lockout tagout software on the market ensures that you have real-time access to information about all your equipment, all the time.

Simple Lockout Tagout Software Implementation

Easy implementation is another important feature included with the best Lockout Tagout software. The setup of a Lockout Tagout program begins with equipment fielding. The best Lockout Tagout software will offer multiple options for loading equipment into the system. A bulk file upload is the fastest and easiest way to add the equipment inventory, so the best Lockout Tagout software will offer this option. It is also important to have a field setup option on the mobile app in case a machine gets missed during the upload. Finally, there should be a field edit option. Sometimes equipment is mis-categorized or mis-labeled on the bulk import spreadsheet, so the best Lockout Tagout software will make it easy to edit incorrect details about a machine from the mobile app. Once equipment is loaded into the system, procedure creation is a snap with the mobile procedure builder.

Conclusion

Developing and maintaining an OSHA compliant lockout tagout program may seem like an overwhelming project, but technology can substantially reduce the workload. When you harness the power of the best Lockout Tagout software, you can build procedures in minutes rather than hours. The best Lockout Tagout software also adds accountability and analytics that are not possible with other programs. We hope you find this information helpful, and that you utilize the best Lockout Tagout software when you develop your Lockout Tagout program.